Commercial Submarine - Capstone

Design Criteria

- Cost-efficient

- Depth rating: 330m to 1000m

- Speed: 2 knots - 6 knots

Introduction

The final capstone project is a major milestone for all aspiring engineering students. It forces us to use all of the skills learned and knowledge gained throughout our degree in one cumulative project. The course is worth twice as much as a regular course, and large deliverables are submitted every other week. Weekly evaluation meetings are held with professors that replicate a professional setting, that many engineers find themselves in. Submitting the final Capstone report is a right of passage for engineers before they fully enter the job market.

Proposed Design

The event also featured workshops, presentations, and a list of social community activities. After two sleepless nights, competitors presented their solutions on the third day and the top 3 teams were picked for each category. My team, CyberMonkE, placed 2nd for the IBM Design Challenge.

Design Criteria

Brief Design Summary

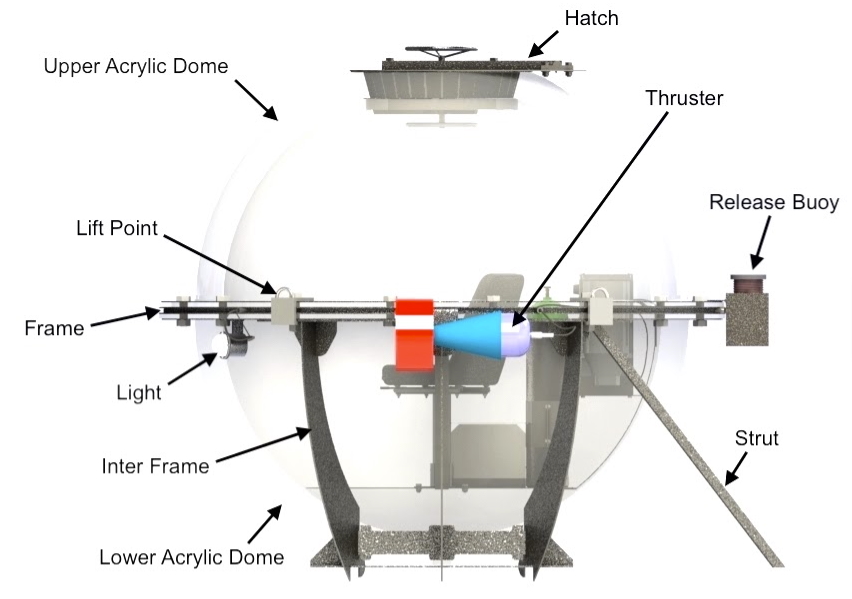

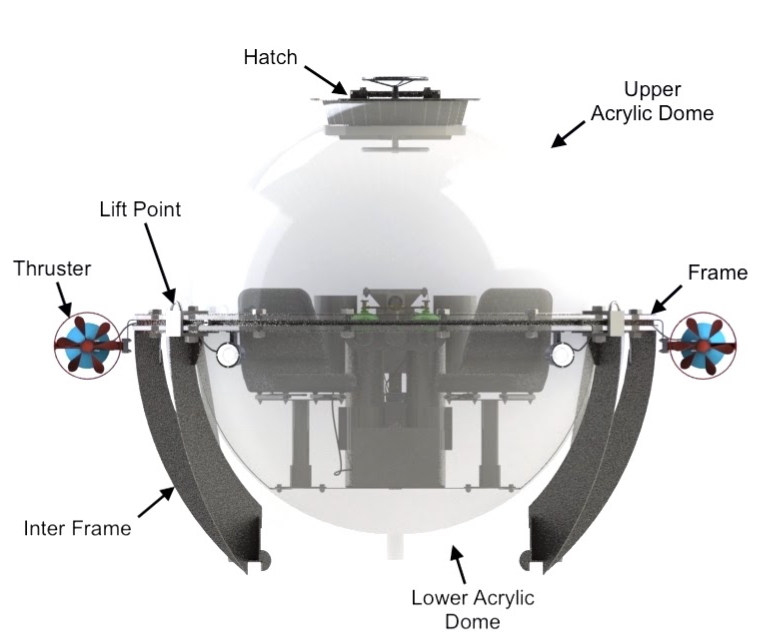

Two translucent acrylic hulls make up the majority of the structure of the submarine. Trying to achieve such high speeds of 6 knots, while maintaining costs low meant that the design had to be minimal and only the most important components were kept, hence the bare-bones look of the submarine. A titanium frame wraps around the hulls to seal them watertight. Titanium was also the primary material used to manufacture the hatch. It was mainly picked due to its corrosion resistance in seawater, which greatly outweighed its high cost.

Large thrusters on each side of the submarine control speed and movement. Up to 6 batteries are placed at the bottom of the submarine (not pictured) in between the main body and the ballasts. Life support inside the submarine contains two oxygen tanks, a control system, and two CO2 scrubbers. A dehumidifier is also included to control humidity and condensation. Four lift points are placed around the frame to allow for deployment and rescue. Expoxy penetrators are used to allowing for wiring from the outside to the inside of the submarine, to allow for use of electrical components.

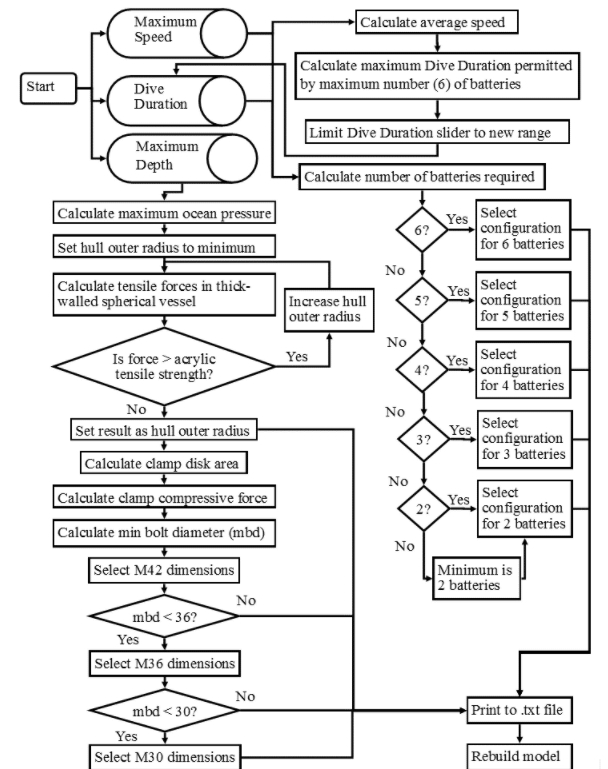

Parametrization

Parametrization was important to the design to allow for clients to input desired speeds, depths, and dive duration. Each input affected the design in a multitude of ways, such as dome thickness, batteries required, etc. The parameterization flow chart shows how the inputs affected certain aspects of the submarine and the intermediate calculations with each changing input.

Conclusion

Finally, the submarine design allowed for a cost-effective, safe, and efficient submersible for commercial uses such as tourism, research, and recreational. The submarine’s minimal design allows it to meet many high-level criteria without largely affecting its weight or cost.

Collaboration with our sister team, which designed the submarine’s ballasts, is one thing that can be improved in the future, to allow for better connectivity between the main body and the ballasts.

Working on this Commercial Submarine Capstone Project was a valuable experience for my team and I. It allowed us to explore an innovative side to engineering that is sometimes lacking from our content-heavy classes.